Home | Departments | Chemical Engineering | Virtual Reality | About

About

Project Background

Process Safety

Most widely accepted definition by Centre for Chemical Process Safety (CCPS, 2010):

A disciplined framework for managing integrity of hazardous operating systems and processes by applying good design principles, engineering, operating and maintenance practices.

- Reduce process safety risks associated with handling hazardous materials and energy

- Help reduce the frequency and consequences of potential incidents

Development of PS Modules

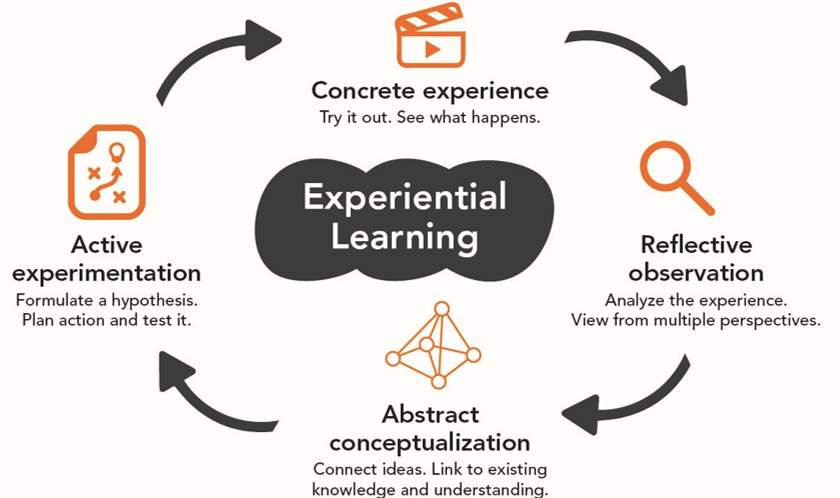

- Learner-centered approach

- Learning is a process where concepts are derived from and continuously modified by experience – ideas are not fixed

- Learning is a tension and conflict filled process

- Begins with here-and-now experience to validate and test abstract concepts

- Continuous process of goal-directed action and evaluation of consequences of that action

- “Any experience that does not violate expectation is not worthy of the name experience”

- Everyone enters every learning situation with some ideas about topic at hand

- Integration tend to become highly stable parts of person’s conception compared to knowledge substitution

- Learning is major process of human adaptation: Short-term performance, long-term mastery, lifelong development

The Lewinian Experiential Learning Model

Teaching of process safety (PS) in engineering undergraduate courses is fundamental. Engineering students should be taught about their role in society and take professional responsibility for public safety in solving complex engineering problems.

However, teaching PS presents a number of challenges. Solely using textbooks or lecture notes is inadequate and opportunities for students to engage and be immersed in actual process industries are scarce in most universities. This results in low interest, poor retention, and poor understanding of PS principles. Students are unable to identify and assess potential hazards in process designs or operating processes and are unprepared for industry.

Generation Z students who are accustomed in this digital age, prefer technology over reading books. By capitalizing on this, educators can adapt the rapidly-growing technology to improve teaching in PS.

Using Virtual Reality (VR) bridges the gap between education and industry 4.0 as humans become integrated into virtual representations of the real world. However, its application in chemical process industries and in teaching undergraduate engineering students is less known. This study aims to use VR learning platforms to enhance students’ learning in PS among chemical engineering students.

The Conceive-Design-Implement-Operate (CDIO) framework is adopted to plan an integrated curriculum with active learning engagement to enhance engineering learning outcomes. Through design-implement experiences, VR will reinforce students’ knowledge and build deeper understanding on PS. Evaluation of the effectiveness and efficiency of teaching and learning with VR in PS is necessary to ensure the objectives are achieved. These can be done by conducting interviews and surveys among stakeholders. In doing this, we aim to produce engineering graduates with better PS awareness and knowledge resulting in future engineers who have better competence, practicality, and ethics in regard to PS.

Expected Outcomes

Students

- Engaging and motivating tool to learn

- Bridging gap between theoretical and practical

- Better retention of PS principles

- Produce graduate engineer with better PS awareness

- Increase competitiveness and employability

- Embrace better safety culture brought to workplace

Educators

- Improve delivery of PS course

- Promote innovation in engineering education

- Provide flexibility on choosing VR as new instructional technique

- Strengthen awareness to nurturing skills to meet future demand of engineering

Industry

- Better readiness and competency of graduate engineers

- Less time and cost to train new onboard engineers

- Reduce occurrence of accidents

- Increase company reputation

- Increase collaboration with academia (align syllabus)

Nation

- Reduce occupational accidents

- Attract overseas investments

- Create better safety policies

- Improve education standards on safety